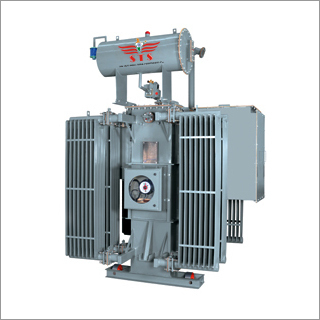

Isolation Transformer

Price 5500 INR/ Piece

Isolation Transformer Specification

- Cooling Type

- AN (Air Natural) / ONAN (Oil Natural Air Natural) as required

- Voltage Booster Type

- N/A (this is not a booster transformer)

- Operating Temperature

- -10C to +45C

- Low Voltage

- As per requirement (commonly 230V/415V)

- Load Loss

- Low, typically 1-2% depending on load

- High Voltage

- Up to 11 kV (as per request)

- Rated Voltage

- 415V/230V (customizable per model)

- Coil Material

- Copper

- Capacity

- 1 kVA to 500 kVA

- Dimension (L*W*H)

- Custom, e.g., 450 x 350 x 500 mm for 10 kVA

- Product Type

- Isolation Transformer

- Material

- Copper windings with silicon steel laminated core; enclosure made from heavy-duty sheet metal.

- Output

- Customizable output according to end-user requirements

- Frequency (MHz)

- 50/60 Hz

- Efficiency

- 98% approx.

- Phase

- Single Phase / Three Phase options available

- Usage

- Industrial and commercial electrical isolation for safety and protection of equipment from power surges, noise, and ground loops.

- Coil Structure

- Toroidal / Laminated core

- Coil Number

- 2 (Primary and Secondary)

- Power Scope

- 1 kVA - 500 kVA

- Weight

- Varies with capacity (e.g., 35 kg for 5 kVA unit)

- Testing

- Routine, Type & Special tests as per IS:2026/IEC 60076

- Protection Grade

- IP 23 / IP 54

- Regulation

- <2%

- Connection Type

- Terminal Block / Cable Lug

- Dielectric Strength

- 2.5 kV

- Humidity Tolerance

- up to 95% RH

- Standards

- IS:2026, IEC 61558

- Insulation Class

- Class F / H

- Noise Level

- <55 dB

- Short Circuit Strength

- High, up to 10x rated current

- Accessories

- Lifting Hooks, Vibration Pads, Terminal Covers

- Mounting Type

- Floor / Base Mounted

- Enclosure Material

- Powder coated steel

- Service Life

- 10-15 years

Isolation Transformer Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 10 Pieces Per Day

- Delivery Time

- 2 Days

About Isolation Transformer

Features:

- High efficiency & safety

- Sturdy construction & reliability

- Good weather resistance

- Cost effective

Product Details:

| Ratios | 1.1 and 2:1 |

| Insulation Resistance | More than 1000 mega ohms. |

| Coupling Capacitance | 0.1 PF for 100 db |

| Leakage Current | Less than 20 Micro Amps |

| Common Model Attenuation | 100 db |

| Regulation | Better than 3.5% |

| Di-electric strength | 2500 V AC for 120 sec |

Specification

| Material | MS |

| Input Voltage | 220 V |

| Phase | 3 |

| Frequency | 50 hz |

Unparalleled Electrical Isolation for Safety

Designed to protect both equipment and personnel, this isolation transformer effectively mitigates risks associated with power surges, electrical noise, and accidental ground loops. Its robust construction, with copper windings and a powder-coated steel enclosure, ensures longevity and dependable operationeven in challenging environments.

Flexible Mounting and Connection Options

Choose between floor or base mounting according to your installation needs. The transformer supports various connection types, such as terminal blocks or cable lugs, allowing seamless integration into new or existing electrical infrastructures. Engineered for both convenience and adaptability, it is suitable for broad commercial and industrial landscapes.

FAQs of Isolation Transformer:

Q: How does this isolation transformer enhance safety and equipment protection?

A: The transformer isolates the input from the output circuit, preventing electrical noise, ground loops, and spikes from reaching sensitive devices. This results in safer operations and extended lifespan for both equipment and personnel, reducing maintenance needs and protecting investments.Q: What are the main standards and tests followed during manufacturing?

A: The transformer is manufactured in compliance with IS:2026 and IEC 61558. Every unit undergoes routine, type, and special testing as per IS:2026/IEC 60076, including dielectric strength tests (up to 2.5 kV), ensuring reliable and safe operation.Q: When and where should this transformer be installed?

A: Installation is recommended in industrial or commercial environments where equipment needs isolation from electrical disturbances. It can be floor or base mounted, and the powder-coated enclosure (IP 23/IP 54) allows for use in environments with dust or moderate moisture, humidity up to 95% RH.Q: What range of power, voltage, and phase options are available?

A: The transformer supports power ratings from 1 kVA to 500 kVA, with voltage customization (typical input/output: 415V/230V) and phase options (single or three phase) to suit varied requirements. High voltage up to 11 kV and custom dimensions/output can be specified.Q: How efficient is the transformer, and what about noise/heat concerns?

A: With an efficiency of approximately 98% and a noise level below 55 dB, the transformer minimizes energy loss and operational sound. Cooling options include Air Natural (AN) or Oil Natural Air Natural (ONAN), based on installation needs and environmental conditions.Q: What is the typical service life and maintenance required for this transformer?

A: Designed for longevity, the transformer offers a service life of 1015 years under standard operational conditions. Minimal maintenance is required thanks to its high-quality copper windings, silicon steel core, and robust enclosure materials.Q: What accessories and installation features enhance usability?

A: Standard accessories include lifting hooks, vibration pads, and terminal covers to simplify installation and ensure safety. Customizable outputs and multiple mounting/connection types provide flexibility for diverse industrial and commercial needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Servo Transformer Category

Distribution Transformer

Price 260000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Efficiency : 98.5%

Coil Structure : Toroidal

Usage : Industrial Power Distribution

Power Scope : Upto 2500 kVA

Step Down Transformers (Air Cooled)

Price 35000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Efficiency : 98% approx.

Coil Structure : Toroidal

Usage : Industrial & Commercial Power Distribution

Power Scope : Upto 5000 kVA

Servo Distribution Transformer

Price 255000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Efficiency : 99%

Coil Structure : Toroidal

Usage : Industrial Power Distribution

Power Scope : Upto 2500 kVA

ISO 9001:2008 certified

|

SERVO TECHNOLOGIES SYSTEM

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry